MAHLE is expecting a significant increase in the variety of drives in the commercial vehicle market. The technology group believes by the year 2035, about 30% of all commercial vehicles worldwide will be purely electric with batteries or fuel cells. MAHLE’s new SCT electric motor (Superior Continuous Torque) provides extremely high continuous power and is therefore especially suited to commercial vehicles. MAHLE newest systems solutions for battery electric drives, fuel cells and cleaner combustion engines can also be fueled with hydrogen. The Group offers modular thermal management systems with greater efficiency and clear cost advantages in all drive variants. MAHLE’s chargeBIG charging infrastructure solution can be experienced on test drives and at the trade fair’s Plug & Play Campus.

“We provide the transport sector’s necessary contribution to climate protection through a realistic and technology-neutral view of customers and markets. We are therefore concentrating our development activities on three areas: battery electric drives and fuel cells, thermal management, and highly efficient, clean combustion engines,” said Michael Frick, Chairman of the MAHLE Management Board (ad interim) and CFO. The commercial vehicle sector is a significant business area for MAHLE: This sector contributes about 20% of the group’s total sales. MAHLE’s customers include all the large global vehicle manufacturers.

The new MAHLE SCT (Superior Continuous Torque) electric motor solves a dilemma common to many electric motors: the great discrepancy between continuous and peak power. While previous electric motors can only provide their peak power for a short time and then drop to around 60 to 70%, the MAHLE SCT electric motor can be operated continuously at over 90% of its peak power. This means it can run indefinitely at high power and is significantly smaller and lighter than a conventional electric motor with the same continuous power. This makes it suitable for use in all vehicle classes, including heavy commercial vehicles. MAHLE achieved the necessary technological leap for the SCT electric motor by using an innovative, integrated oil cooling system. With the introduction of the new electric motor, MAHLE becomes a full-range supplier in the field of electric drives. Its offerings range from pedelecs and e-scooters to passenger cars and delivery vans, as well as heavy-duty commercial vehicles, off-road vehicles, and industrial applications, MAHLE electrifies everything that runs on wheels.

“We are addressing exactly those issues that still pose a particular challenge to our customers when developing electric vehicles: cruising range, performance, fast charging capability and comfort in the driver’s cabin,” said Dr. Martin Berger, Head of Corporate Research and Advanced Engineering at MAHLE. Thanks to a portfolio breadth unrivaled in the industry, the group can perfectly coordinate individual components and subsystems. This is the most important prerequisite for an efficient complete system, especially with battery electric drives.

MAHLE has expertise in air management, filtration, thermal management, and electronics. The technology group uses this expertise in its latest fuel cell technologies. The preparation of the outside air before it is fed to the fuel cell is of particular importance. MAHLE air filters protect the fuel cells from particles and harmful gases with absolute reliability and throughout the entire service life of the vehicle. A modular concept makes the application simple and cost-effective. To be able to work optimally, fuel cells need humid air. MAHLE’s flat membrane humidifier accomplishes this. It increases efficiency and protects the cell from drying out. Reliable humidification is also very important for maintaining a level of efficiency and contributes to the long service life of these expensive components. MAHLE developed the flat membrane humidifier in conjunction with other partners. This development was sponsored by the Federal Ministry for the Economy and Climate Protection (BMWK). To stabilize the voltage provided by the fuel cell across all load ranges, the company has developed a high-voltage DC/DC converter. It covers high outputs of up to 180kW, reaches an efficiency of more than 97% and achieves very high-power density. With the sophisticated thermal management, MAHLE maps the essential systems in fuel cell peripherals.

In addition to the fuel cell, the use of hydrogen as a combustion fuel has the potential to make many heavy-duty and off-highway applications climate-neutral particularly quickly. Hydrogen engines are ideal for high load cycles with sudden load steps and handle heat, contamination, and vibration well. At MAHLE, more than 100 years of experience flow into the development of the necessary engine components. A new power cell unit will be presented for the first time at the IAA, a system consisting of pistons, piston rings, conrods, pins and, if necessary, a cylinder liner as well as a high-pressure impactor for flushing the crankcase. This means that hydrogen can be used highly efficiently and safely in combustion engines with a long service life.

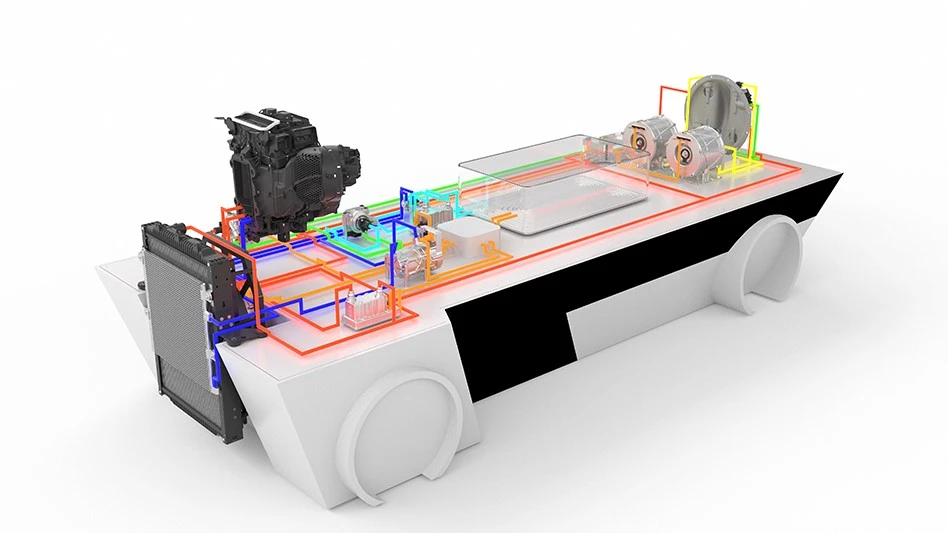

Thermal management, vehicle heating and cooling, is of particular and overarching importance in the development of efficient CO2-neutral drives. Complexity and demands on its performance increase significantly in battery electric drives and fuel cell systems.

“In view of the increasing diversification in the drive mix for commercial vehicles, it is our task to offer our customers the right solution for all drive types. We must keep an eye on costs because the transport industry is still sensitive here,” says Dr. Roger Busch, head of global development for the thermal management business unit.

This is achieved through a modular structure of the system. Ideal system architecture can be developed for every application and every vehicle and the large number of individual driving profiles and vehicle classes in the commercial vehicle sector can be covered with high efficiency and at optimal costs. The core components of the system are the cooling module, air conditioning, high-voltage heater, electric compressor, battery and electronic cooling systems, coolant pump and an oil management module for temperature control of the electric motor.