© TRUMPF

TRUMPF Photonic Components, a global leader in VCSEL solutions for industrial laser heat treatment, is showcasing its latest TruHeat VCSEL product developments for area heating and e-mobility applications at Photonics West 2024 in San Francisco, California. The VCSEL-based laser heating systems offer direct, homogeneous, and zone-controllable heat treatment for industrial processes.

“One example that we will showcase is our next generation of TruHeat VCSEL systems for battery foil drying, offering even higher efficiency and supporting lower power densities,” says TRUMPF Photonic Components Vice President of Marketing and Sales Ralph Gudde. “High process quality due to homogeneous heating and illumination zone control, fast processing, a small footprint, and lower CO2 emissions are the benefits that our customers get,” Gudde adds.

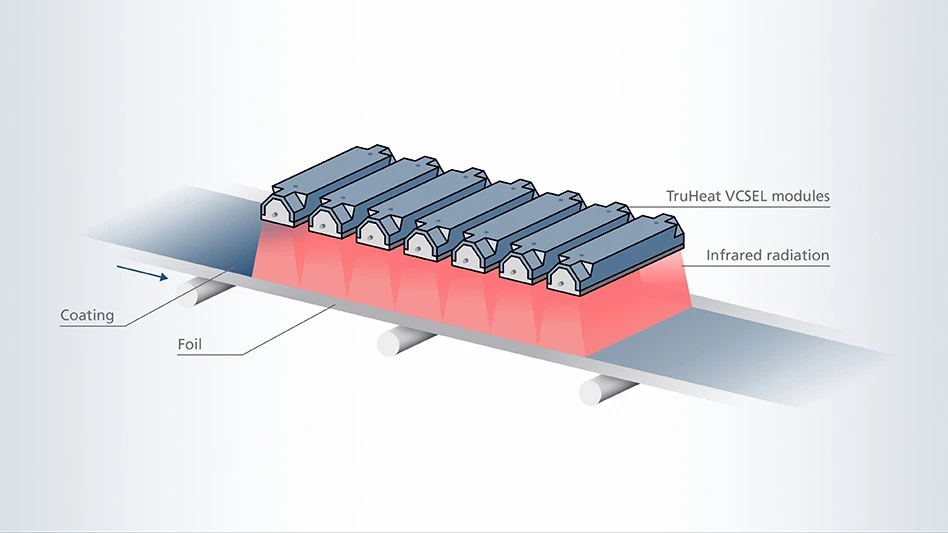

Novel TruHeat VCSEL laser heating systems for battery foil drying applications

The drying of electrode coatings is a delicate process and consumes most of the energy in Li-ion battery manufacturing due to the use of very large and inefficient convection ovens. Laser drying offers several advantages, like improved energy efficiency, reduced floor space, and increased process control. Therefore, TRUMPF developed the TruHeat VCSEL laser heating systems to enable the homogeneous drying of very large surfaces with relatively low power densities. TruHeat VCSEL laser heating systems are based on the latest generation multi-junction VCSEL arrays, and the heating system is optimized for thermal design with highly efficient driver electronics. The wavelength of 980nm is strongly absorbed by all battery electrode materials and therefore supports the high drying efficiency.

The TruHeat VCSEL laser heating systems have a modular design with separate zones. This enables the tight control of individual illumination zones to support not only optimal homogeneity but also the customization of intensity profiles, for example, a lower or higher intensity at the edges of the coating.

Visit TRUMPF Photonic Components at Photonics West 2024, Booth 833.