CREDIT: WALTER

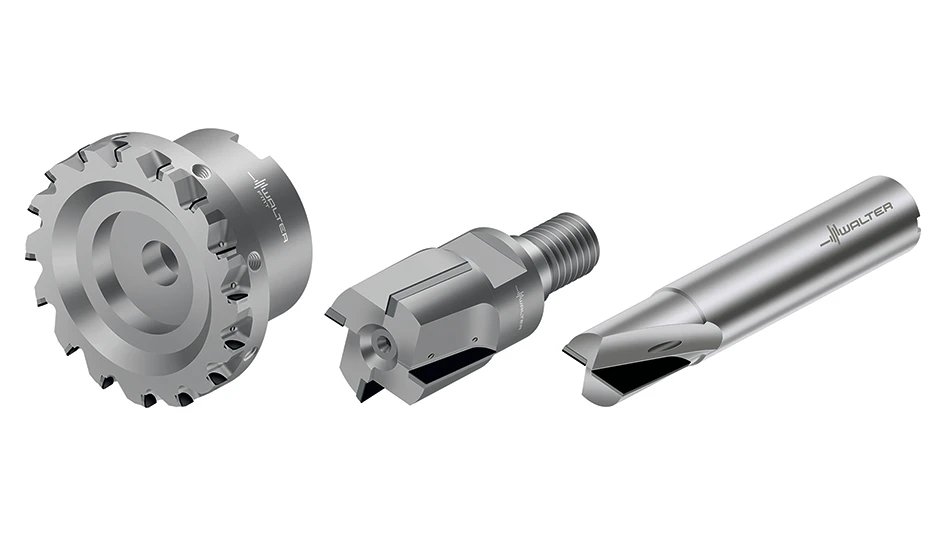

The MP060, MP160, and MP260 milling cutters from Walter have brazed PCD cutting edges and are for machining aluminum, aluminum-silicon alloys, magnesium alloys, plastics, and fiber composite materials (ISO N and ISO O, or other material groups). The new tools are for automotive, aerospace, electronics, and general mechanical engineering applications with the finest surface quality specifications.

The MP060 face milling cutter has from 10 to 22 teeth (z = 10-22) and is available with a diameter from 40mm to 125mm. It is suitable for roughing and finishing large surfaces and flat shoulders. It features threaded holes that accept balancing screws.

The MP160 shoulder and slot milling cutter is available with either a cylindrical shank or ScrewFit adaptation and is available with a diameter from 16mm to 40mm. The tool has three or four teeth (z = 3-4), and is suitable for ramping, helical drilling, and full slotting.

The MP260 routing cutter is also available with cylindrical shank or ScrewFit adaptation and is available with a diameter from 4mm to 20mm. It has two or three teeth (z = 2-3) and is suitable for plunging, full slotting, and milling small flat surfaces.

All three PCD milling cutters are equipped with an internal coolant supply and can be used with emulsion or minimum quantity lubrication (MQL). Their service life is 20 to 200x longer than that of solid carbide cutters, which is primarily the result of being made with Walter’s wear-resistant poly-crystalline diamond WDN20 grade, as well as because of reduced cutting forces and a low-vibration microgeometry.

In addition to providing cost-effective, precise machining, the MP060, MP160, and MP260 PCD milling cutters require fewer tool changes than carbide cutters due to their longer service life. Tools at least 6mm in diameter can be reconditioned to extend the service life.