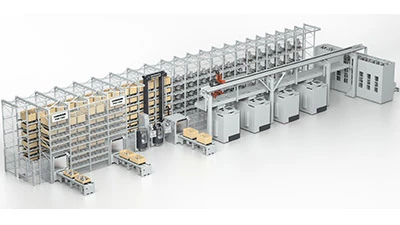

Liebherr Automation Systems introduced the PHS Allround pallet handling system, designed to enable a range of shops to engage in flexible production in combination with 4- and 5-axis machining centers. The modular concept, available in three capacities, can handle loads up to three tons, is flexible, and can be individually configured and expanded. This corresponds to pallet sizes of 500mm x 500mm to 1,000mm x 1,000mm. Users can introduce flexible production systems with manageable investment and expand them when necessary.

Preconfigured modules can be combined as needed to match production handling needs: the storage locations can be arranged in a circular pattern, with one or more machines, or in a line.

This system fits in almost every production floor. The user can easily expand a production system with the Allround, spreading investment over different expansion stages.

For all Liebherr pallet handling systems (RLS, PHS Pro, and PHS Allround), Liebherr offers a new cell control with simple operation. The graphically-guided interface concentrates functions on the main computer in a user-friendly manner, and if required, allows full production control. This includes resource planning, cutting tools, and NC data management, plus interfaces to the ERP systems.