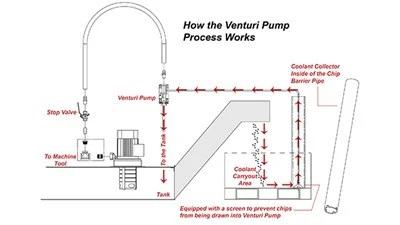

Cincinnati, Ohio – Removing coolant that naturally accumulates in a chip hopper enables longer production runs, eliminates messy cleanouts and reduces coolant costs. A new venturi pump kit from LNS makes the process of removing coolant from chip hoppers virtually effortless.

The easy-to-install kit continuously draws coolant from the chip hopper through a filtering screen and returns it to the machine tool tank, eliminating cutting fluid waste and allowing the hopper to hold more chips. As a result, there are fewer interruption of production runs, and the messy job of cleaning out coolant-filled chip hoppers is eliminated.