CREDIT: GF MACHINING SOLUTIONS

To support the global shift towards electrification, silicon carbide (SiC) wafers are increasingly used in powering electronics and radio frequency components. Their widespread use arises from their exceptional thermal conductivity, stability, mechanical strength, and wide band gap, enabling electronic components to operate at higher capacities.

SiC wafers have diverse applications, including converters, inverters, battery chargers, and power supplies, and are utilized across various industries such as automotive, renewable energy, telecommunications, defense, and information and communications technology (ICT).

A complex manufacturing process: why is profiling required?

The deployment of SiC wafers presents sophisticated machining challenges for manufacturers across the entire chain, from monocrystal growth to integrated circuit (IC) packaging. Traditionally, manufacturing processes have been better suited to applications involving silicon (Si). However, machining silicon carbide (SiC) for wafer production involves working with a much harder material using techniques that are not fully optimized for this purpose.

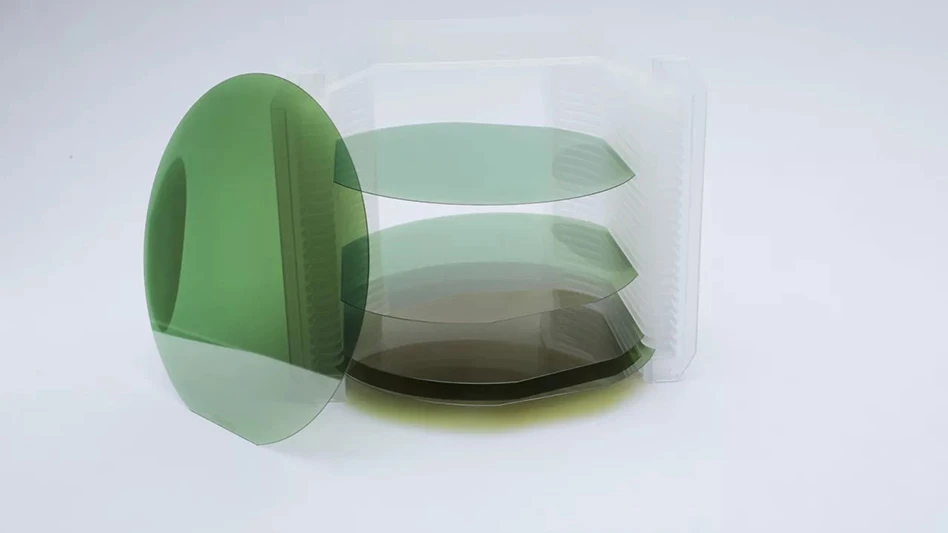

Throughout the manufacturing process, SiC wafers, generally 6" to 8" in size, are handled multiple times. Their extreme hardness and brittleness significantly increase the risk of chipping or breakage. To mitigate this risk, SiC wafers are given edge profiles (usually R- or F-type) according to SEMI standards. These profiles are typically created using diamond wheel grinding, which faces issues such as diamond wheel wear, uneven grinding, and improper angle formation. This current process is time-consuming and results in high manufacturing costs.

A new process by GF Machining Solutions

GF Machining Solutions’ latest innovation, the LASER S 500 U, is an advanced laser ablation machine combining high dynamics with precise thermoregulation, delivering unparalleled edge profile quality, accuracy, and consistency.

The LASER S 500 U offers several significant advantages that transform the manufacturing process. By using non-contact technology, it eliminates tool wear, ensures process reliability, and maintains consistent quality over long production runs without the risk of breakage. In terms of efficiency, the LASER S 500 U significantly reduces processing times, from hours to just a few minutes. It also substantially lowers the cost per part by eliminating the need for expensive grinding tools.

Additionally, the combination of the machine and GF Machining Solutions’ proprietary CAM software, LaserSUITE360, enables the creation of any edge profile, notch shape, or wafer size. These benefits are achieved through an innovative process that integrates a completely integrated solution from CAD/CAM to machining execution, performed at extremely high speeds due to high dynamic movements, innovative machining strategies, and stable accuracy.

Opening more possibilities

The solution enhances wafer processing with advanced features, such as embedded camera technology that precisely identifies critical areas and reads identification numbers. This allows scraped 8" wafers to be resized into new 6" wafers, completed with their specific identification numbers, all processed with the same solution.