CREDIT: AVERY DENNISON

Avery Dennison Performance Tapes introduced a new EV Battery Venting Materials Portfolio to help counter the risk of thermal runaway and increase safety in electric vehicle (EV) batteries. These venting solutions include single- and double-coated anisotropic filmic tapes with proprietary fire-barrier coatings and pressure-sensitive adhesives (PSA) for bonding.

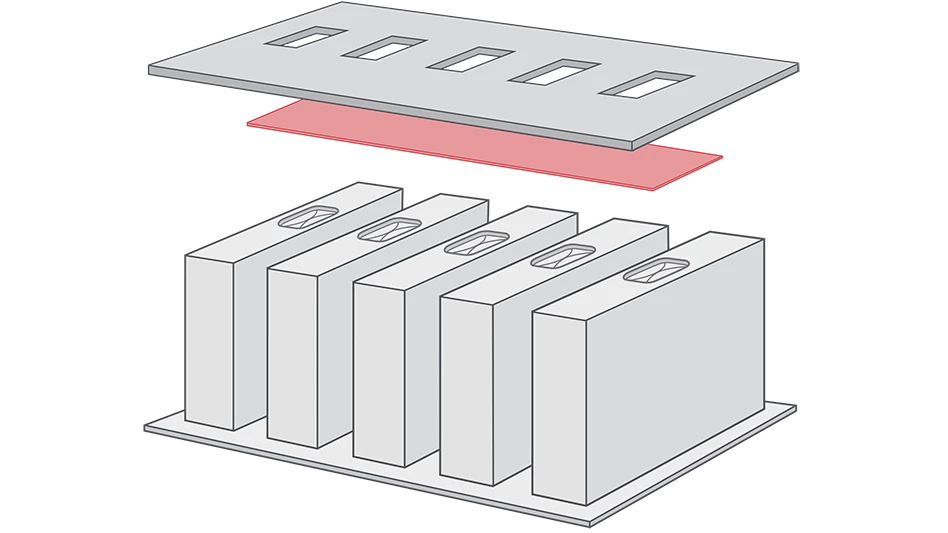

EV battery manufacturers implement venting strategies at the cell, module, and pack levels. The Avery Dennison battery venting tape solutions, when applied to module or pack level venting holes, provide quick burn-through to facilitate venting via a channel. The opposite side provides extended flame resistance to prevent the migration of flames and hot gases into adjacent cells. The outer side of the film will last less than four seconds under flame. The adhesive side will last longer than 15 seconds. The combined flame retardancy is designed to counter the risk of thermal runaway.

“Our new venting solutions are engineered to provide differential performance to flame exposure, which can lead to very elegant emergency venting strategies,” says Max VanRaaphorst, business development manager, eMobility, Automotive & Energy Storage, Avery Dennison Performance Tapes North America. “These unique tapes can be combined with a wide range of other thermal runaway mitigation materials to lead to efficient, space saving designs. As always, our goal is to help make EV battery packs more safe, efficient and easier to assemble.”

Avery Dennison venting material solutions offer:

- A more economical alternative to complex mica parts

- Roll-to-roll application covering wide areas

- Space-saving thin profile

- Ease of application, whether manual or automated

- Several colors available for vision systems

- Customization for thickness and color, combined with materials such as aluminum foil or mica to meet burn-through requirements