Courtesy of Cetec ERP

AUSTIN, TX (March 19, 2024) - Cetec ERP, a cloud-based ERP software provider, has developed a powerful new inventory management feature called Pre-Allocation. The feature is tailored to contract manufacturers in any supply chain vertical and addresses the common pain point of managing inventory across multiple projects or programs.

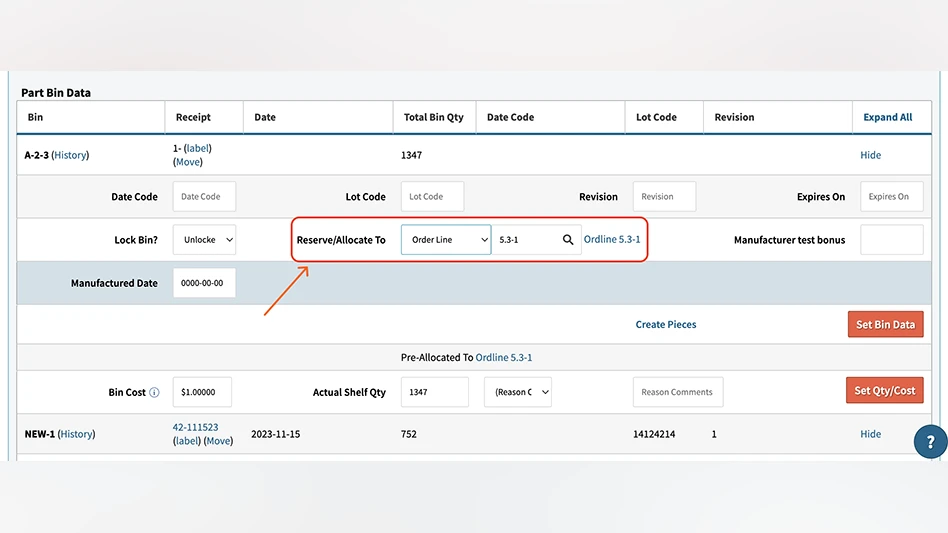

The Pre-Allocation feature facilitates the early assignment of materials to specific projects and customers, allowing users to designate a customer or work order directly on the supplier’s purchase order or existing on-hand inventory. The tool ensures that customer-supplied inventory is not shared, and that work orders have appropriate inventory allocated to prevent slowdowns in production. By allowing early inventory assignment, contract manufacturers can address key inventory management challenges, such as preserving customer-supplied inventory for the right jobs, material planning for large projects and programs, and protecting estimated costs.

For medical device contract manufacturing organizations (CMOs), pre-allocation simplifies the complexities of tracking and tracing inventory across multiple customers and projects. It raises visibility on true shortages, without adding manual effort to know which PO or lot/batch belongs to which order. Additionally, it helps keep track of customer-supplied inventory.

Pre-Allocation also simplifies material planning and strengthens inventory oversight, ensuring that materials are dedicated to intended projects ahead of production, thus streamlining operations and enhancing project delivery accuracy.