CREDIT: TRUMPF

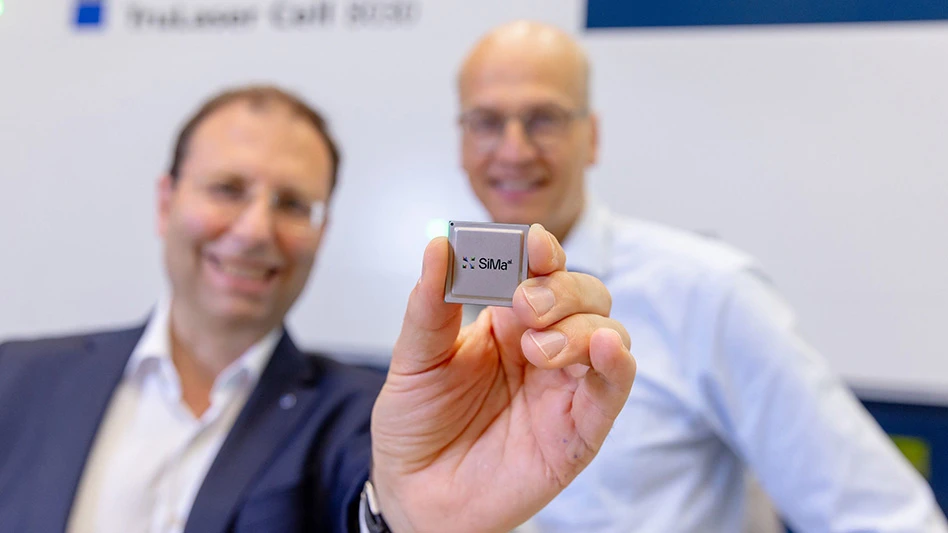

The high-tech company TRUMPF and SiMa.ai, the software-centric, embedded edge machine learning system-on-chip company, signed a partnership to develop lasers with artificial intelligence (AI). The goal is to equip several laser systems of TRUMPF with AI technology in the near future. This includes systems for welding, cutting, and marking, as well as powder metal 3D printers.

"AI has high strategic relevance for TRUMPF. Our expertise in laser processes and manufacturing helps us to develop smart software for production purposes. SiMa.ai is the ideal partner for this next big step towards intelligent industrial solutions," says TRUMPF Laser Technology’s Chief Technology Officer Richard Bannmüller

Both companies bring their respective expertise to the collaboration: TRUMPF, its laser application expertise, and SiMa.ai, its machine learning system on chip (MLSoC) technology.

“The rapid acceleration of AI innovation is reshaping how humans can leverage emerging technology – SiMa.ai’s powerful MLSoC and flexible software alongside TRUMPF’s highest level of process understanding is enabling AI solutions that drive the industry forward. In combination with TRUMPF's advanced AI software, SiMa.ai’s one software-centric platform for all edge AI adjusts to any framework, network, model, sensor, or modality, making it possible to reach the next level of AI-assisted laser technology,” says SiMa.ai Head of Sales and President of Automotive Business Harald Kröger. SiMa.ai, headquartered in San Jose, California with offices in Stuttgart, Germany, employs approximately 200 employees. Edge ML applications that run completely on SiMa.ai’s machine learning system on chip see a tenfold increase in performance and energy efficiency, bringing higher fidelity intelligence to ML use cases spanning computer vision to generative AI, in minutes. At TRUMPF, approximately 90 employees worldwide are working on AI, primarily in product development.

Accelerated production of electric vehicles

The joint collaboration intends to accelerate complex material processing. The powerful, compact, and energy-efficient AI chips will be integrated directly into the laser systems. The AI-optimized sensor technology can monitor the quality of the laser welding process in real time and evaluate more than 3,000 images per second. In electric car production, for example, the real-time quality inspection during laser welding with the help of artificial intelligence (AI) is expected to replace separate and complex testing procedures. Moreover, battery manufacturers will be able to increase the quality of their production in real time and reduce the reject rate which could ultimately lower the price of electric cars for consumers.

Latest from EV Design & Manufacturing

- Charge up for holiday travel with electric vehicle battery range calculator

- Hot isostatic press combines multiple heat treatments in one system

- 3 Questions with an Expert: Mitutoyo

- Memorandum of Understanding aims to strengthen U.S. critical mineral supply chain

- Optimize your manufacturing applications with the right metrology tools

- Honda unveils demonstration production line for solid-state batteries

- Navigating today’s supply chain

- Multi-energy platform for trucks and SUVs designed for versatile production