CREDIT: KAIST

Accurately diagnosing the state of electric vehicle (EV) batteries is essential for their efficient management and safe use. Korea Advanced Institute of Science and Technology (KAIST) researchers have developed a new technology that can diagnose and monitor the state of batteries with high precision using only small amounts of current, which is expected to maximize the batteries’ long-term stability and efficiency.

KAIST (represented by President Kwang Hyung Lee) announced that a research team led by Professors Kyeongha Kwon and Sang-Gug Lee from the School of Electrical Engineering had developed electrochemical impedance spectroscopy (EIS) technology that can be used to improve the stability and performance of high-capacity batteries in electric vehicles.

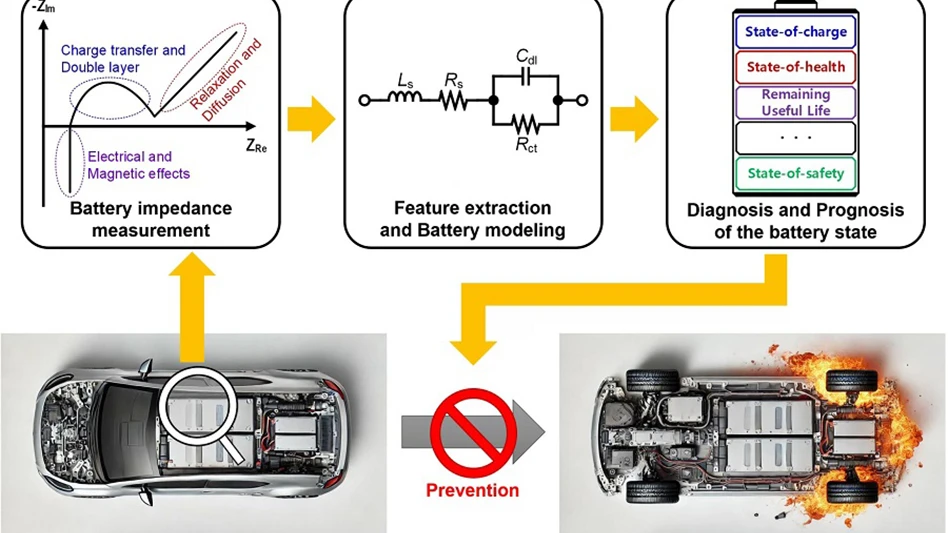

EIS is a powerful tool that measures the impedance magnitude and changes in a battery, allowing the evaluation of battery efficiency and loss. It is considered an important tool for assessing the state of charge (SOC) and state of health (SOH) of batteries. Additionally, it can be used to identify thermal characteristics, chemical/physical changes, predict battery life, and determine the causes of failures.

However, traditional EIS equipment is expensive and complex, making it difficult to install, operate, and maintain. Moreover, due to sensitivity and precision limitations, applying current disturbances of several amperes (A) to a battery can cause significant electrical stress, increasing the risk of battery failure or fire and making it difficult to use in practice.

To address this, the KAIST research team developed and validated a low-current EIS system for diagnosing the condition and health of high-capacity EV batteries. This EIS system can precisely measure battery impedance with low current disturbances (10mA), minimizing thermal effects and safety issues during the measurement process.

In addition, the system minimizes bulky and costly components, making it easy to integrate into vehicles. The system was proven effective in identifying the electrochemical properties of batteries under various operating conditions, including different temperatures and SOC levels.

Professor Kyeongha Kwon (the corresponding author) explains, “This system can be easily integrated into the battery management system (BMS) of electric vehicles and has demonstrated high measurement accuracy while significantly reducing the cost and complexity compared to traditional high-current EIS methods. It can contribute to battery diagnosis and performance improvements not only for electric vehicles but also for energy storage systems (ESS).”

This research, in which Young-Nam Lee, a doctoral student in the School of Electrical Engineering at KAIST participated as the first author, was published in the international journal IEEE Transactions on Industrial Electronics.

Latest from EV Design & Manufacturing

- Fast tracking the development of custom rupture disk prototypes

- EMUGE-FRANKEN expands precision thread gage line

- IMTS 2024 Booth Tour: Fagor Automation Corp.

- How Robotics and Automation are Transforming Manufacturing

- Plug & Charge integration and roaming solution aims to make EV charging more user-friendly

- Automatic tool change solution released for turning centers

- IMTS 2024 Booth Tour: Marubeni Citizen-Cincom, Inc.

- Startup introduces EV battery health measurement system