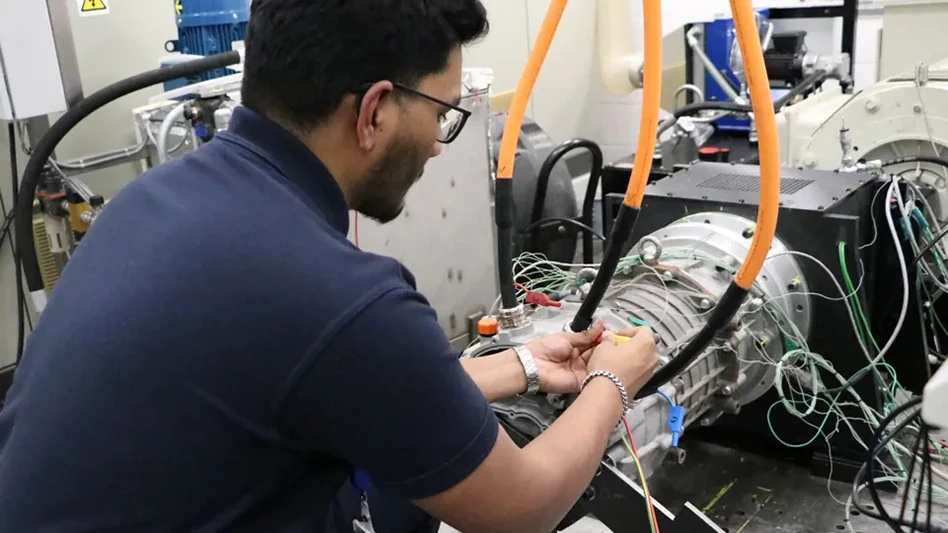

CREDIT: DIAMOND QUANTA

Any major industrial or technological transition takes time, and transitioning from the internal combustion engine (ICE) to electric vehicles (EVs) is no exception. It’s a large shift, which means there are plenty of kinks to be ironed out. The performance and safety of the vehicles themselves, along with the batteries that power them, have improved immensely through years of research and development (R&D). Another concern, though, is where and how to source the materials EVs require. As production ramps up, the industry must avoid depleting natural resources to build the machines heralded for their environmental benefits.

When it comes to potential shortages caused by EV production, lithium may be the most well-known, as it’s a vital component in most EV batteries, and a good deal of R&D is going into alternatives such as sodium or just better recycling options. There’s also, however, a supply chain issue with another major EV requirement: semiconductors. While the semiconductor industry has rebounded after a shortage a couple of years ago, it’s still unstable, with some experts predicting another shortage may impact the automotive industry in the near future.

In contrast, one material is available in abundance – and it may surprise you. Diamonds have long been known for their rarity, which is part of why they’ve been so prized, not to mention expensive. About two decades ago, however, lab-produced diamonds, after years of research and effort, began to appear on the market with quality matching their mined equivalents. Adam Khan, an undergraduate studying physics and electrical engineering at the University of Illinois Chicago, read an article about the potential of these human-made diamonds for not only jewelry but electronics applications, and began to get ideas.

Khan would go on to do graduate work at Stanford Nanofabrication Facility, specializing in condensed matter physics. His specific areas of work included diamonds for optics, photonics, quantum computing, and quantum sensing applications, as well as semiconductors. This led to the founding of AKHAN Technologies, a company focused on researching diamond-based semiconductor devices. In January 2024, Khan started a new company called Diamond Quanta to market semiconductor and quantum technology solutions based on those years of research.

The diamond advantage

Semiconductors are vital for the operation of EVs, facilitating the conversion of energy from the battery into the power that drives the motor. They also play a role in monitoring the battery’s health, charge level, and temperature. An EV may contain thousands of semiconductors, with the exact number depending on the vehicle’s model – many more than in ICE vehicles, leading to increased demand. Silicon is currently the most commonly used semiconductor material; it’s inexpensive and widely available but has limitations, particularly regarding temperature. While it possesses high heat resistance and thermal conductivity, modern electronics require more. Think of how hot your cell phone gets if you’ve been using it for a while, then apply that to something much larger, such as an EV.

“The temperature of electronics limits electric vehicles’ range and you need to have a dedicated cooling loop,” Khan says. “The system becomes quite heavy, and that really limits the range and charging efficiency of that platform.”

Adding carbon to silicon creates silicon carbide (SiC), which has become more commonly used in EV power inverters because of its superior thermal conductivity and weight reduction capabilities. Diamonds, however, can reduce weight even further, and they are operational at more than 400°C – compared to 180°C for SiC and 120°C for silicon. In addition, since lab-grown diamonds have entered the market, there’s a surplus of them. These synthetic gems have environmental and humanitarian benefits over mined diamonds, but, according to Khan, they can also be better tuned to specific applications.

The Unified Diamond Framework

Diamond Quanta developed an approach called the Unified Diamond Framework (UDF), which examines diamond’s electronic structure to better understand its capabilities for semiconductor and other electronic applications.

“We've combined models from quantum thermal statistics, from topology, and from the electromagnetism aspect to form a complete framework where we can understand the unique geometry of diamond,” Khan says. “We can understand how the charge moves across the diamond bulk material, and then the ability to engineer that at the atomic and molecular level, to make devices and essentially dictate where the charge will be transported per device structure.”

The UDF addresses issues that have limited the ability to produce diamonds for electronic applications – specifically doping issues. Doping refers to the practice of adding foreign atoms to a material to change its properties; for example, doping a semiconductor material can change its electrical conductivity. Previous attempts at doping diamonds caused their physical properties to degrade, but the UDF circumvented these defects to effectively add both negatively (n-type) and positively (p-type) charged atoms to diamond semiconductors.

Diamond-based semiconductors, with their increased heat resistance and capability to handle higher power density than other materials, enable more compact and lightweight EV batteries. This results in increased range and efficiency for EVs, which, added to the reduction in mining, makes lab-grown diamonds an appealing option for sustainably-minded manufacturers. However, according to Khan, lab-grown diamonds offer less obvious environmental benefits as well.

“Diamond is made from methane, predominantly,” he says. “And methane is the most abundant molecule in our universe. It's exceptionally easy to fabricate methane, and tying that into the urgency to reduce methane and CO2 levels worldwide, the ability to capture methane at the landfill and farm level and then put that into something productive, like developing and manufacturing chips, has an eco-virtuous cycle attribute that really excites me.”

Latest from EV Design & Manufacturing

- Battery with built-in fire extinguishing technology moves electric vehicle safety forward

- Axial flux motor accelerates e-mobility

- MARBEL project develops modular, eco-friendly electric vehicle battery

- ChargeTronix releases distributed EV charging system, third-generation chargers

- US electric vehicle sales start off strong in the first quarter of 2025

- SES AI launches battery material discovery software and service platform

- ChargePoint develops high-speed AC Level 2 electric vehicle charging capabilities

- Vibracoustic designs air springs suited to electric pickup trucks