CREDIT: GIE MEDIA

High-temperature alloys, also known as superalloys, are extremely valuable in applications such as aerospace manufacturing, as they can be machined at temperatures of more than 1000˚F (540˚C) while resisting corrosion and oxidation. Nobody’s perfect, however, and these materials, which include titanium, Inconel, and others, are notoriously difficult to machine. Upcoming webinar Mastering High-Temp Alloys: 3 Machining Strategies for Solid End Milling Aerospace Components, taking place Tuesday April 22 at 12PM ET, will address the challenges in solid end milling these alloys for aerospace applications.

This interactive session will feature three experts from Kennametal, supplier of superalloy tooling solutions to OEMs around the world, as they detail three key machining strategies:

- roughing with ceramic end mills

- traditional roughing and finishing

- dynamic milling with solid carbide end mills

Danny Davis, Steve George, and Katie Myers will highlight the advantages of each of these techniques and to what applications they’re best suited, connecting machining principles to specific aerospace components. Learn, ask questions, and come away from this free event with new insights on how you can optimize superalloys for your manufacturing applications.

Speaker Highlights

Katie Myers

Product Manager Marketing

Kennametal

Katie Myers, recipient of the prestigious Women MAKE Emerging Leaders 30 Under 30 Award by The Manufacturing Institute in 2024, has made significant strides in her career at Kennametal since joining in 2015. Starting as a co-op student in the Global Machining Technology Lab, she excelled in new product development testing and customer part processing for solid end mills. Today, as a global product manager, Katie has helped increase Kennametal’s solid end mill portfolio by 25%. In 2022, she co-founded the first U.S. employee resource group for Kennametal, Women at Work, and is a member of Kennametal’s Regional Inclusion Council. She has become a regular spokesperson for Kennametal’s solid end milling category and holds a degree in mechanical engineering.

Danny Davis

Senior Staff Engineer

Kennametal

Danny Davis is a senior staff engineer with 42 years of experience at Kennametal. His responsibilities focus on design and application support for solid end mills. He collaborates closely with many Kennametal customers to ensure they correctly apply their end mills for the best performance and process optimization. He also assists customers with any custom tool designs that may be needed. Danny has been named as an inventor on multiple patents at Kennametal.

Steve George

Senior Manager Product Design Engineering

Kennametal

Steve George is the global leader of Kennametal’s solid round tools RD&E team and brings 30 years of knowledge on tool design, performance testing, and machining calculations to the role. He began his career as a co-op engineering student working in Kennametal manufacturing plants and progressed through various manufacturing and RD&E roles. He has published multiple research papers on milling and chip formation and is a named inventor on more than 20 U.S. patents. His passion for machining and solving challenging problems is evident in the success of Kennametal’s end milling product lines.

Can’t participate on the day of the event? No problem! Each registered attendee will also receive a link to the recording. This content will be sent approximately 5 business days after the event.

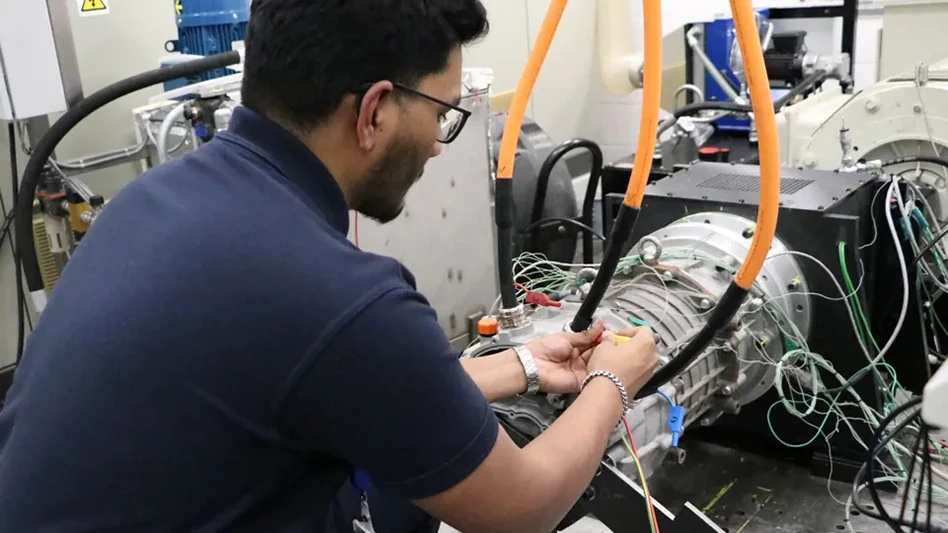

Latest from EV Design & Manufacturing

- Battery with built-in fire extinguishing technology moves electric vehicle safety forward

- Axial flux motor accelerates e-mobility

- MARBEL project develops modular, eco-friendly electric vehicle battery

- ChargeTronix releases distributed EV charging system, third-generation chargers

- US electric vehicle sales start off strong in first quarter of 2025

- SES AI launches battery material discovery software and service platform

- ChargePoint develops high-speed AC Level 2 electric vehicle charging capabilities

- Vibracoustic designs air springs suited to electric pickup trucks