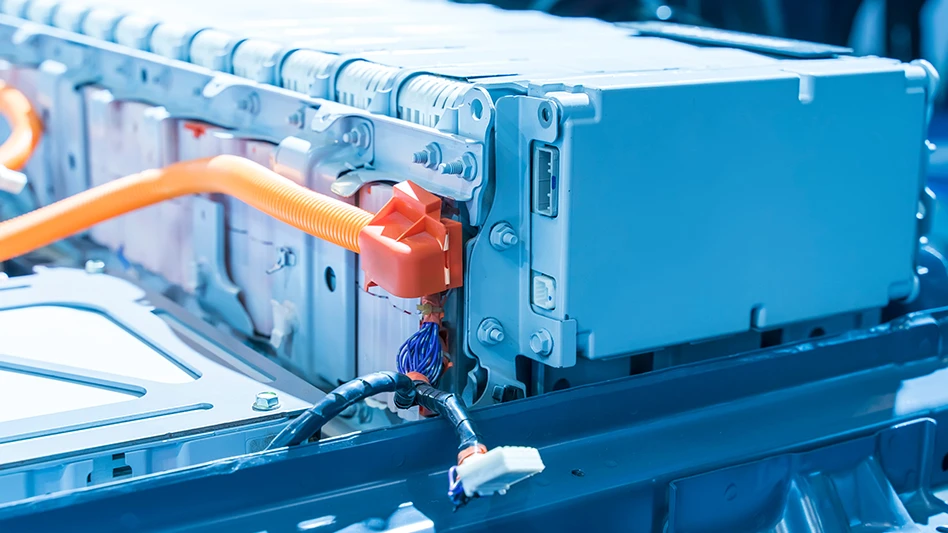

CREDIT: PROLOGIUM TECHNOLOGY

Battery solutions provider ProLogium Technology premiered its 100% silicon composite anode battery at the 2024 Paris Motor Show. This technology, certified by TÜV Rheinland, is also adopted in partnership with Germany's FEV Group to develop a next-generation battery pack, showcasing ProLogium's substantial progress in lithium ceramic battery (LCB) commercialization and introducing a new concept to the market.

"Our next-generation battery technology effectively addresses many of the challenges in the electric vehicle industry. Our goal is to be a game changer in the market, injecting new energy into the electric vehicle sector," states Vincent Yang, ProLogium's founder and chairman.

The new battery system not only surpasses traditional lithium-ion batteries in energy density and charging efficiency but also addresses critical industry challenges. Its fast-charging capabilities help overcome the shortage of charging stations and improve the residual value of used vehicles. This debut marks ProLogium's accelerated progress toward the commercialization of lithium ceramic batteries.

ProLogium Technology's new 100% silicon composite anode significantly enhances energy density and fast-charging performance. The system achieves a volumetric energy density of 749Wh/L and a gravimetric energy density of 321Wh/kg, with projections to increase to 823Wh/L and 355Wh/kg by the end of 2024. Dr. Dmitry Belov, chief scientist of ProLogium Technology, states: "Our new technology has broken through existing barriers. Since 2023, we've consistently outperformed our competitors, with the gap only growing larger, in both energy density and in fast-charging performance."

Compared to mainstream lithium iron phosphate (LFP) batteries (under 200Wh/kg), and nickel manganese cobalt (NCM) batteries (200 to 300Wh/kg), ProLogium's LCB has already surpassed current lithium-ion batteries on the market, with the gap expected to widen by up to 77% by the end of the year. According to TÜV Rheinland test data, the battery charges from 5% to 60% in just 5 minutes and reaches 80% in 8.5 minutes. This advancement greatly reduces charging time and extends vehicle range, significantly enhancing overall performance.

With its battery offering increased energy density and fast-charging capabilities, ProLogium has introduced the "Small Battery, Big Future" concept, offering a blend of efficiency, performance, and sustainability.

With only 66% of the total energy capacity of current lithium-ion batteries (from 83kWh to 55kWh), ProLogium has cut vehicle weight by 300kg, boosting both energy efficiency and driving range for an enhanced driving experience. This reduction in battery capacity also translates into lower carbon taxes and decreased initial vehicle costs.

Additionally, a 5-minute charge provides an approximate range of 300km, outpacing the industry's 30-minute average. This ultra-fast charging reduces wait times by 83.3%, improving efficiency and turnover rates while addressing pressing challenges of limited charging stations and long wait times.

ProLogium's modular design allows for easier repairs and facilitates cell recycling, reducing maintenance costs and increasing the resale value of used electric vehicles. Together, these four features directly contribute to a reduced total cost of ownership (TCO), offering consumers a more affordable and sustainable EV solution.

The "Small Battery, Big Future" concept effectively tackles industry dilemmas such as low EV residual values, the inability to replace individual cells, and the environmental impact of scrapped vehicles.

Another key highlight of this debut is the unveiling of ProLogium and FEV's strategic partnership at the Paris Motor Show, showcasing how the battery packs are integrated into electric vehicles. This collaboration marks ProLogium's progression from producing EV components to developing battery modules and packs, underscoring the company's substantial strides in commercialization. Dr. Thomas Hülshorst, global vice president electric powertrain at FEV, states: "Over the past two years, our collaboration has resulted in customized battery packs and concept designs that not only meet, but exceed regulatory standards and market demands. Due to the significantly increased energy density of the LLCB cell of 321Wh/kg, the energy storage system can be designed to be smaller and lighter for a vehicle with a targeted driving range, thus reducing power and space requirements. By combining ProLogium's visionary technology with FEV's engineering strengths, we are paving the way for the future of sustainable mobility."

Latest from EV Design & Manufacturing

- Honda unveils demonstration production line for solid-state batteries

- Navigating today’s supply chain

- Multi-energy platform for trucks and SUVs designed for versatile production

- Solution offered for easy EV charger mounting in commercial spaces

- Bridging the Skills Gap: A Solution for Today’s Labor Shortage

- Fast tracking the development of custom rupture disk prototypes

- EMUGE-FRANKEN expands precision thread gage line

- IMTS 2024 Booth Tour: Fagor Automation Corp.