GIE Media's Manufacturing Group

Monday September 9 3:15 PM CST

IMTS15 Room W192-C

Learn about the presentation

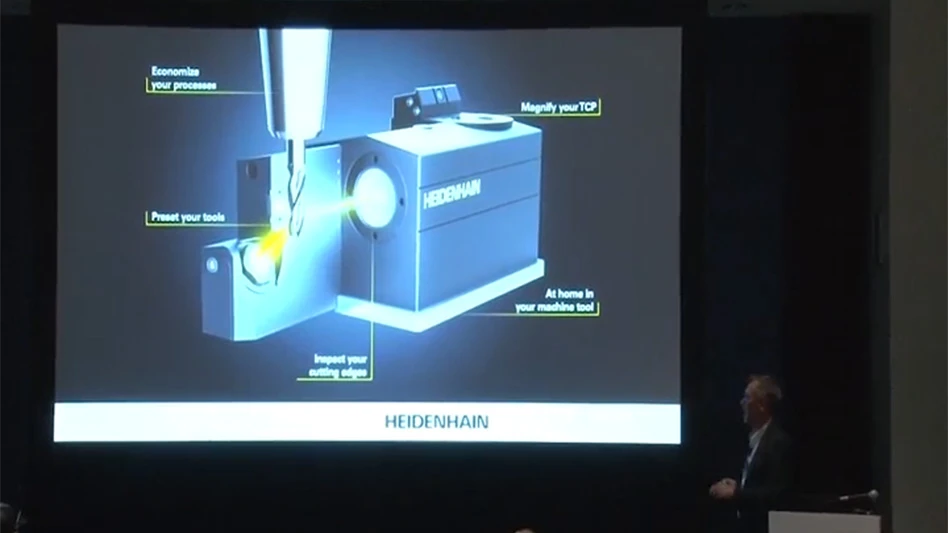

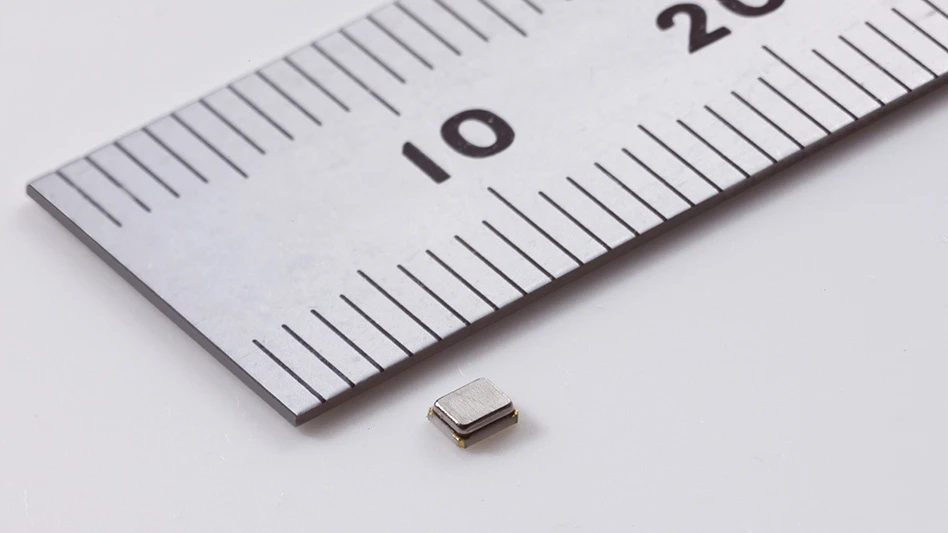

The manufacturing industry is undergoing a digital transformation, with more factories connecting industrial equipment like machine tools to collect data and gain insights. One area where this connectivity is making an impact is in cutting tools and tool holders equipped with sensors. In this presentation, a technical expert from Sandvik Coromant will discuss the capabilities of sensorized tooling, including measuring temperature, vibration, strain, and other metrics in real-time during machining operations. Attendees will learn how sensor data can be used to optimize machining parameters, predict tool wear and failures, and ultimately improve productivity. The presenter will outline the technical considerations in developing sensorized tooling to withstand harsh machining environments. There will also be an overview of data connectivity options and how tool data can integrate with wider factory systems. While sensorized tooling requires upfront investment, the speaker will make the case for how the data and insights it provides can drive significant long-term cost savings and efficiency gains across manufacturing processes. The presentation will equip the audience with an understanding of this important emerging technology poised to help advance manufacturing into a more connected, intelligent future.

Meet your presenter

With over 43 years of industry experience, Jeff Rizzie's technical expertise has centered around manufacturing processes with a concentration on metal cutting and machine tool integration as well as implementation of Industry 4.0 based technologies. Following the latest trends in data and analytics, Jeff combines his manufacturing background with his knowledge of advanced digital technologies to positively impact customer success. He also has extensive international strategic planning, implementation, and leadership experience working to drive and support key initiatives of manufacturing customers and internal stakeholders that ultimately enhance the customer experience.

Latest from EV Design & Manufacturing

- Fast tracking the development of custom rupture disk prototypes

- EMUGE-FRANKEN expands precision thread gage line

- IMTS 2024 Booth Tour: Fagor Automation Corp.

- How Robotics and Automation are Transforming Manufacturing

- Plug & Charge integration and roaming solution aims to make EV charging more user-friendly

- Automatic tool change solution released for turning centers

- IMTS 2024 Booth Tour: Marubeni Citizen-Cincom, Inc.

- Startup introduces EV battery health measurement system