General Motors

General Motors Co. and POSCO Future M announced the second phase of their Ultium CAM joint venture, an investment projected to exceed $1 billion (U.S.) to increase production capacity of CAM in North America and integrate precursor materials production. pCAM is a specifically engineered combination of processed raw materials necessary to produce CAM, a key battery material representing about 40% of the cost of a battery cell. Currently, CAM and pCAM processing is highly concentrated in Asia.

GM is executing plans to install 1 million units of annual EV capacity in North America in 2025, supported by four U.S. battery cell joint venture plants with 160GWh of capacity and grow from there in subsequent years. The Ultium CAM joint venture will support production of approximately 360,000 Chevrolet, Cadillac, GMC, Buick and BrightDrop vehicles annually in the 2025-2030 timeframe in North America.

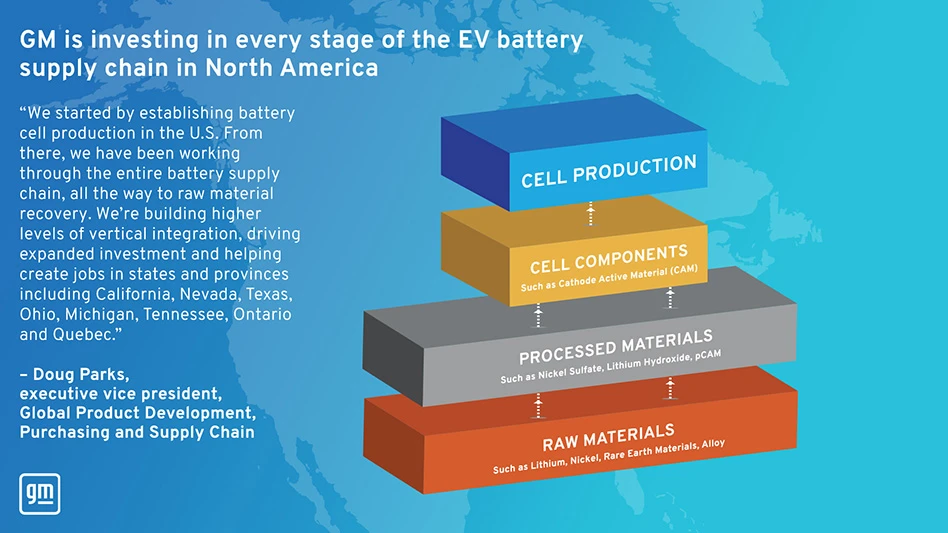

“Increasing CAM production capacity and adding pCAM to our joint venture is another significant step in building a more secure and sustainable North America-focused supply chain to support GM’s fast-growing EV production needs,” says Doug Parks, GM executive vice president, Global Product Development, Purchasing and Supply Chain. “We started by establishing battery cell production in the U.S. From there, we have been working through the entire battery supply chain, all the way to raw material recovery. We’re building higher levels of vertical integration, driving expanded investment, and helping create jobs across North America.”

"We are experiencing rapid growth of the EV battery materials market across North America. I believe our joint venture will fortify its position in the secondary battery material industry with this proactive decision to increase CAM production and bring pCAM production to North America," says Kim Joon-Hyung, President, POSCO Future M. "POSCO Future M's advanced technology and experience is supported by our expanding partnership with GM. We are aiming to play a key role in the eco-friendly mobility market with our products."

The companies established the Ultium CAM joint venture, which is majority owned by POSCO Future M, in July 2022. Site selection will be announced later.

The announcement is the latest in a series of actions GM has taken to build a more secure EV supply chain. A timeline of GM’s major supply chain development appears below:

Raw material recovery and processing

- July 2021 - Announced strategic investment and commercial collaboration with Controlled Thermal Resources to develop California-sourced lithium extracted from geothermal brine

- Dec. 2021 - Announced long-term supply with MP Materials for U.S.-sourced and manufactured rare earth materials, alloy and finished magnets. MP Materials is establishing the first North American processing site for alloy flakes, and will expand into magnet manufacturing at their new production facility in Ft. Worth, Texas

- Dec. 2021 - Announced plan with POSCO Future M to produce CAM in Canada; site work in Quebec commenced in March 2022

- April 2022 - Announced multi-year sourcing agreement with Glencore for sustainable cobalt from Australia

- July 2022 - Announced six-year agreement with Livent beginning in 2025 for battery-grade lithium, with the goal of transitioning 100% of Livent’s downstream lithium hydroxide processing for GM to North America

- July 2022 - Announced supply agreement with LG Chem, which will provide GM with more than 950,000 tons of CAM over eight years, enough for approximately 5 million units of EV production

- July 2022 - GM announced it has reached binding agreements with its supplier partners to achieve its target production rate of more than 1 million EVs annually in North America in 2025

- Oct. 2022 - Announced strategic collaboration with Queensland Pacific Metals (QPM) of Australia for long-term supply of nickel and cobalt

- Nov. 2022 - GM announced agreement with Vale to source nickel from Canada

- Dec. 2022 - Ultium Cells LLC signed a supply agreement with POSCO Future M to source artificial graphite from Korea

- Jan. 2023 - GM announced supply agreement and $650 million equity investment in Lithium Americas to develop the Thacker Pass lithium mine in Nevada - the largest-ever investment by an automaker in battery raw materials; construction commenced in March 2023

Cell manufacturing and R&D

- Dec. 2019 - GM formed the Ultium Cells LLC joint venture with LGES for U.S. battery cell production

- Oct. 2021 - GM announced Wallace Battery Cell Innovation Center in Warren, Michigan, to expand battery technology operations and accelerate development and commercialization of longer range, more affordable EV batteries

- Aug. 2022 - Ultium Cells LLC began ramp up of battery cell production in Warren, Ohio

- April 2023 - GM and Samsung SDI announced plan to build a new battery cell manufacturing plant in the U.S.

EV components

- Sept. 2022 - GM announced investment in its Toledo, Ohio, propulsion manufacturing operations to prepare the facility for production of drive units that will be used in future Ultium-based battery electric trucks

- Nov. 2022 - GM announced binding long-term agreement with Vacuumschmelze (VAC) for North America magnet production

- Feb. 2023 - GM announced plans to build EV motors for BrightDrop light commercial vehicles at its St. Catharines, Ontario, propulsion plant.

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?