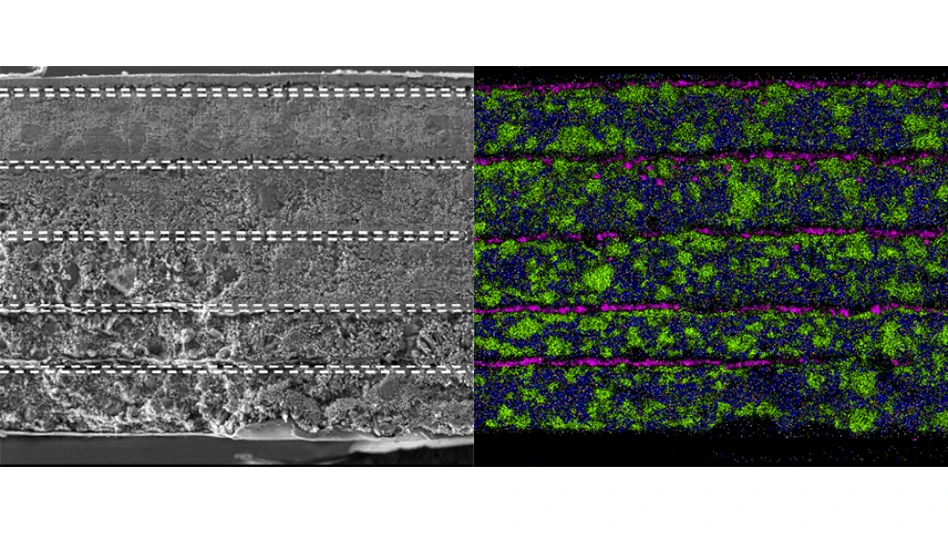

CREDIT: FORGE NANO

Forge Nano, Inc., a materials science company that uses its Atomic Armor Atomic Layer Deposition technology to optimize material performance to enable better products, announced a $10M investment from GM Ventures, the venture arm of General Motors. The investment adds to its previous $50 million Series C with participation from Hanwha, Orion Infrastructure Capital, Catalus Capital, and Ascent Funds. The company has raised more than $100 million to date with additional investments from Volkswagen, Mitsui Kinzoku, LG Technology Ventures, Sumitomo Corporation of Americas, Air Liquide, and SBI Investment.

The GM Ventures investment positions Forge Nano to further enhance its Atomic Armor platform technology, which allows for the application of thin coatings to the surface of materials or objects to enhance the underlying substance’s performance and durability. Forge Nano intends to continue to expand its battery material coating business, which includes in-house active material coating services, external equipment sales, and production of Atomic Armor-powered battery cells, as well as expand its footprint in semiconductors.

General Motors and Forge Nano have also signed a strategic partnership agreement to utilize the company’s high-throughput Atomic Armor equipment to coat cathode active materials for GM’s EV battery cells to increase performance and lifetime. Through the partnership, Forge Nano will continue to build upon its expertise in engineering next-generation battery materials to advance their performance capabilities alongside GM. GM expects Forge Nano’s innovative coating technology to advance its lithium-ion technology roadmap that will allow for an improved electric vehicle ownership experience. Forge Nano intends to develop thin-film coatings to enhance GM’s cathode active materials and build prototype lithium-ion battery cells at its Colorado headquarters to showcase the enhancement capabilities of Atomic Armor.

“GM Ventures’ primary goal is to bring disruptive technology into the GM ecosystem to improve products and processes,” says Anirvan Coomer, managing director of GM Ventures. “Forge Nano’s Atomic Armor technology has game-changing potential for our battery materials at significant scale. They have already demonstrated the ability to expand cathode capabilities, which is the most expensive battery cell component. This could unlock benefits for customers and the business.”

Forge Nano has demonstrated its ability to enhance battery-grade materials, including graphite, silicon, and various formulations of nickel-rich cathodes, to unlock peak performance battery cell products for its customers.

“Forge Nano’s mission is to make better materials for a better world. General Motors’ investment will allow us to further enhance battery material performance and durability, while allowing us to expand our footprint in other key areas – like semiconductors,” says Paul Lichty, CEO of Forge Nano. “We look forward to working closely with GM to enhance battery cell performance for future electric vehicles.”

Forge Nano’s battery material enhancement capabilities are also expected to be showcased through Forge Battery – the company’s battery manufacturing business – which was recently selected for a $100M award negotiation with the U.S. Department of Energy to expand its production capacity.

Forge Battery has begun producing and shipping 300Wh/kg Atomic Armor-powered lithium-ion prototype cells using Forge Nano’s Atomic Armor surface engineering platform technology. The newly formed company intends to produce best-in-class high-energy and high-power lithium-ion battery cells for defense, aerospace, and specialty electric vehicle markets at a newly constructed gigafactory in Raleigh, North Carolina. Forge Battery plans to utilize a U.S-focused battery material supply chain to further bolster the domestic battery ecosystem and reduce reliance on foreign suppliers.

Latest from EV Design & Manufacturing

- Industry leaders partner to deliver load management, smart charging and energy solutions

- Anti-vandalism systems designed to increase electric vehicle charging station security

- GM selects Vianode as anode graphite supplier for electric vehicle batteries

- AMADA WELD TECH introduces blue laser technology into micro welding portfolio

- Despite hurdles, consumer interest in electric vehicles is rising

- Vehicle-to-grid charging technology expanded with new product line

- In-line CT delivers real-time quality feedback on the production line

- Join our editors for a look at the manufacturing industry in 2025