DEES Hydraulic Industrial Co. Ltd.

1) HOT-FORMING PRESSES TAME ULTRA-HIGH-STRENGTH STEEL AND FIRM ALUMINUM ALLOYS.

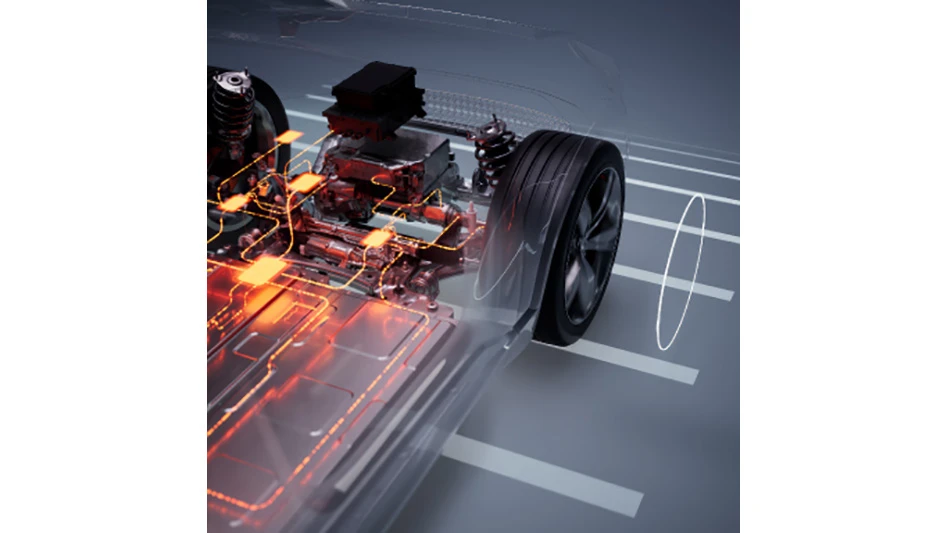

Hot forming steel and alloys supports lightweight, high-strength car bodies and frames, components revolutionizing automotive manufacturing. DEES integrates Industry 4.0 technologies into hot forming, automating, and collecting data with the transfer system.

DEES has successfully established hot-forming lines for certain high-strength steels, the most difficult materials to form, so lower temperature aluminum and other alloys will be less challenging. The technology has become increasingly common throughout Europe.

We expect the technology to become more common as DEES and other providers show how heat can shape high-strength materials, overcome post-forming bounceback issues, and provide accuracy for finished parts.

Carbon-fiber reinforced plastic (CFRP) composite materials are also popular for European manufacturers, and DEES has produced several composite hot-forming systems as well.

Latest from EV Design & Manufacturing

- Hyundai unveils latest hybrid powertrain system

- Daanaa Resolution introduces Power Transaction Unit for power conversion

- 3 Questions with an Expert with Allied Machine & Engineering

- CATL one-ups BYD with latest fast-charging electric vehicle battery development

- Vertical turning centers offer precision, efficiency

- April Manufacturing Lunch + Learn with Iscar

- April Manufacturing Lunch + Learn with Insaco

- Lyten expands domestic battery supply chain with US-produced lithium