As the Industrial Internet of Things (IIoT)/Industry 4.0 (I4.0) changes manufacturing, one area ripe for intelligent automation is energy management. Monitoring compressed air consumption in pneumatic systems can reduce emissions, detect leakages, and lower energy costs. Many manufacturers assume that IIoT/I.40 requires extensive engineering hours to connect and deploy hardware and software systems, but there are plug-and-play devices that monitor air consumption of existing systems with minimal setup.

A global automotive producer recently partnered with Emerson Electric to monitor and measure energy on an existing production line, investing in Emerson’s Aventics AF2 series flow sensor.

Production line challenges

The automaker hoped to reduce energy consumption with an IIoT/I4.0-enabled energy management tool on an existing production line. A typical brownfield scenario, the production line involved legacy equipment pieces – each one from a different supplier. Each meter box has a power supply, Ethernet bus coupler, power meter (one per circuit), and IO-Link with eight available ports for sensors. To facilitate air circulation, modules had to be installed upright. Complicating matters, the company had a limited number of Ethernet access points, preventing expansion at a reasonable cost.

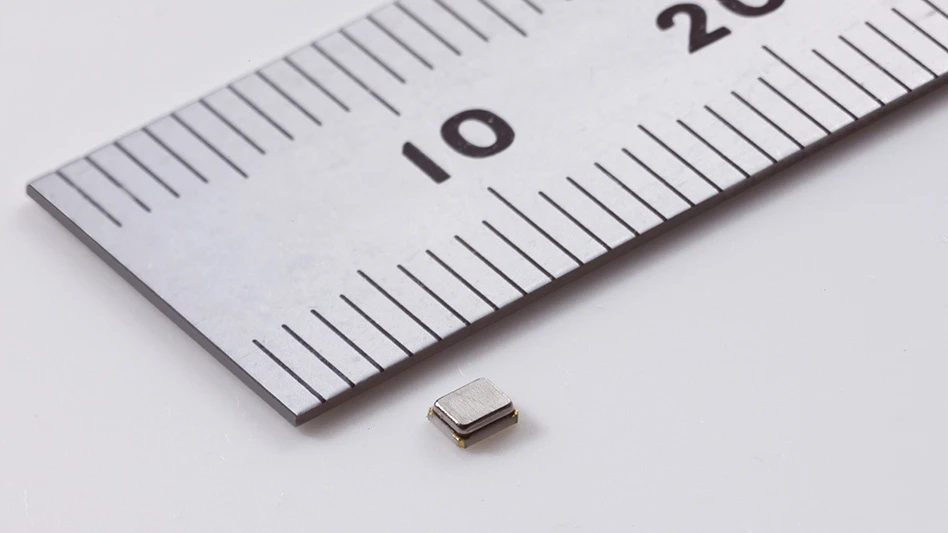

Emerson’s Aventics series AF2 flow sensor monitors air consumption in pneumatic systems and provides actionable insights, enabling quick intervention if a leak is detected, preventing downtime and reducing maintenance costs and energy consumption.

Emerson supplied roughly 180 AF2 sensors along with the RXi2 edge computing gateway with PACEdge, which digitizes all incoming data from AF2s, turning it into easy-to-understand information. The information is recorded and displayed on a live, web-based dashboard.

Emerson’s first approach was to temporarily connect the Aventics Smart Pneumatic Analyzer (SPA) to one machine to record, analyze, and visualize air consumption. The SPA, which displays air consumption in normal liters per minute (Nl/min) and supplements the displayed live value with average and maximum values, enabled the team to quickly detect trends and anomalies.

Early data showed the customer that investing in the RXi2 platform would save more energy and cost. The updated system gives the automaker better visibility into energy consumption, including ways to reduce leakage-related waste within the normal operating parameters of the machine. The customer identified areas for improvement, including reducing peak power consumption, optimizing maintenance costs, and avoiding downtime.

Conclusion

Combining the AF2 flow sensor and RXi2 edge computing gateway provides an all-in-one energy-saving sensing and edge computing solution. The package monitors pneumatic air consumption, generating and interpreting machine data, leading to actionable insights and a complete picture of what’s happening in the plant. Now, the automaker has a better understanding of air consumption on its production lines and can optimize its machines for reduced energy use.

Emerson Electric Co. https://www.emerson.com/aventics

Latest from EV Design & Manufacturing

- Fast tracking the development of custom rupture disk prototypes

- EMUGE-FRANKEN expands precision thread gage line

- IMTS 2024 Booth Tour: Fagor Automation Corp.

- How Robotics and Automation are Transforming Manufacturing

- Plug & Charge integration and roaming solution aims to make EV charging more user-friendly

- Automatic tool change solution released for turning centers

- IMTS 2024 Booth Tour: Marubeni Citizen-Cincom, Inc.

- Startup introduces EV battery health measurement system