Session Topic: Breaking Free of the Additive Manufacturing Echo Chamber

Monday, 9/9, 10:00AM – 10:55AM / Room W192-A

The additive manufacturing (AM) industry is an echo chamber – exacerbating its own hype, hindering collaboration, and stifling growth. The current map to success has provided AM technology with an honorable, but minimal foothold in the expansive and overarching manufacturing landscape. With limited recognition outside of its own LinkedIn community, the AM industry is facing a fork in the road – to continue with bespoke, artistic application design for advanced, but focused industries, or to take the on-ramp to the greater manufacturing highway.

The AM industry’s path to more substantial and mainstream manufacturing opportunities is not paved with design ingenuity and futuristic ideation of traditional applications. It is paved with reliability, manufacturing redundancy, and supplemental manufacturing. AM’s purpose in the larger manufacturing industry isn’t to re-design the road of production – it’s to fill in the potholes of supply chain gaps that create unnecessary risk on the global economy highway.

In this presentation, Dr. Hayes will discuss:

- How the next generation of the AM industry can build upon its foundation while establishing strategies outside of its traditional comfort zone

- How reliability and interchangeability in manufacturing techniques can mitigate supply chain risk

- How shifting from sexy to boring will breed success for the AM industry

Gregory Hayes

Senior Vice President of Global Additive Minds

EOS

Dr. Gregory Hayes is the senior vice president of Global Additive Minds at EOS with a strong background in high-end research and development, and a focus in materials science and engineering. Hayes’ professional background began as a consulting materials scientist and technical program lead, working internationally in the health-tech, high-tech, and aerospace markets.

Currently, Hayes works to identify market needs and uses of additive manufacturing technology to develop products to fulfill business development opportunities. Previously, as a program manager and director of new partnerships for AM at TNO, Hayes concentrated on design and structure of research programs, acquisition of funding and partners, and general management. Hayes also co-founded Complex Materials, a bespoke bioresorbable materials company with a focus on magnesium alloy stent tubing.

Hayes holds an ME degree from the University of Delaware; a Ph.D. in Materials Science from The Pennsylvania State University; and Start-up and Entrepreneurship certification from the Vlerick Business School in Belgium.

EOS provides responsible manufacturing solutions via industrial 3D printing technologies to organizations around the world. Since 1989, EOS has shaped the future of manufacturing by enabling its customers to innovate and differentiate through expert guidance, technology and services, leveraging its end-to-end additive manufacturing (AM) industry partnerships. From strategy to education to production, EOS is the leading global partner for both metal and polymer AM solutions, accelerating time-to-market for its customers through high-quality production efficiencies and sustainable solutions.

IMTS 2024 booth #432302

https://www.eos.info

Explore the IMTS 2024 Conference Guide Issue

Check out more from this issue and find your next story to read.

Latest from EV Design & Manufacturing

- Lucid to acquire select facilities and assets from Nikola Corp.

- CNC coordinate measuring machine for large parts, complex applications

- Battery with built-in fire extinguishing technology moves electric vehicle safety forward

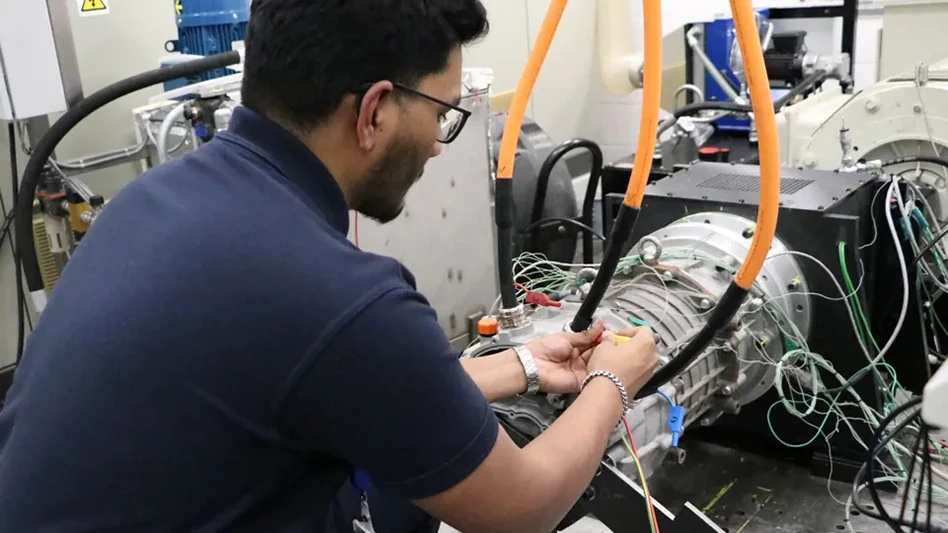

- Axial flux motor accelerates e-mobility

- MARBEL project develops modular, eco-friendly electric vehicle battery

- ChargeTronix releases distributed EV charging system, third-generation chargers

- US electric vehicle sales start off strong in first quarter of 2025

- SES AI launches battery material discovery software and service platform